Range of AnalysesMicrostructural analysis

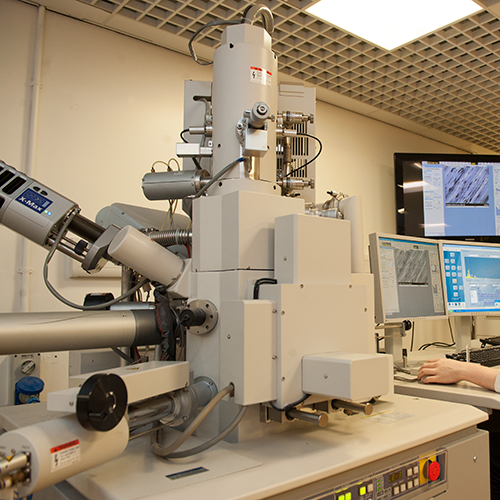

Scanning Electron Microscopes (SEM)

With the HITACHI S-3700N tungsten filament SEM and the HITACHI SU-6600 high-resolution field emission FE-SEM, we can perform a variety of analyses:

- Morphological and topographical imaging

- Surface fractography

- Materials microstructure

- Grain size and texture analysis by electron backscattered diffraction (EBSD)

- Scanning transmission electron microscopy (STEM) on thin films

- Variable pressure mode for non-conductive specimens – i.e. no need for carbon/gold coat

- Non-destructive analysis on small components through a large chamber (300 x 110mm)

- In-situ micro-mechanical tests (2kN load cell and video capture)

- Environmental capability.

X-Ray Diffractometer (XRD)

- The BRUKER D8 ADVANCE with DAVINCI XRD extracts structural information material and phase identification from metals and ceramics

- Analysis can be completed at ambient and elevated temperatures up to 2000oC

- Specimens can be in bulk or powder form, thin films, corrosion products or debris

- Measured properties include phase composition, crystal structure, lattice parameters and mismatches, spatial orientation of crystals, crystallinity, residual stress, grain texture, and layer thickness.

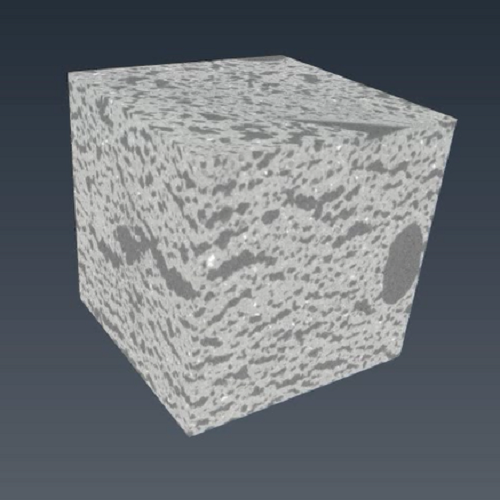

X-ray Computed Tomography Scanner

- The Nikon XT H 225 LC non-destructively produces high-resolution (1.5μm) volume images of any material based on density contrasts

- Measures porosity and permeability characterisation, deformation in a solid medium, phase characterisation and in-situ feature measurement

- Liquid or dry environment

- Deben CT 10kN cell for specimens imaging in real time under controllable environmental conditions

- 225kV X-ray source of reflection and transmission.

Optical Microscopy (OM)

- The Olympus GX51 inverted microscope suitable for observations of metallographic specimens

- Wide variety of observation methods including brightfield, darkfield, differential interference contrast, polarisation

- Magnification range from x50 to x1000

- Image capture with a 3Mp digital camera.

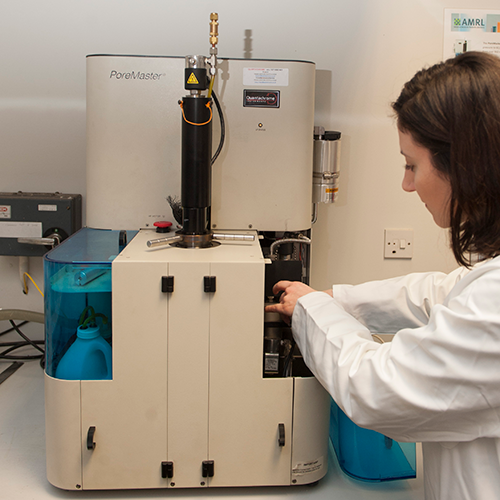

Mercury Intrusion Porosimetry (MIP) can be completed on special request

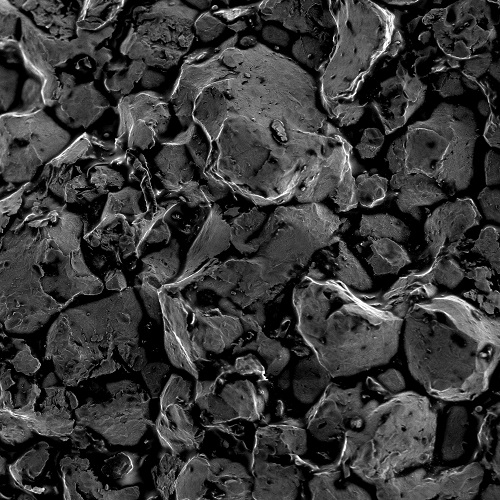

SEM scan showing brittle intergranular fracture