Wind Turbine DecommissioningRenewable Parts Ltd

Overview

Renewable Parts Ltd

- Company: Renewable Parts Ltd (RPL) is a leading supply chain and refurbishment specialist focusing on wind turbine parts and supplies and the refurbishment and components for the wind sector.

- Location: Lochgilphead

- Industry Sector: Wind energy supply chain

- Size: 35

- Project Result: The project will enable RPL to develop a sustainable business model and technical solutions for remanufacturing parts and components from decommissioned wind turbines to give them another lease of life.

KTP Aims

The aim of the KTP is to use circular economy principles to develop a sustainable business model for wind turbine decommissioning, and state-of-the-art metrology and remanufacturing techniques to resell and/or repurpose parts and components from decommissioned wind turbines. This will develop a strategic business knowledge around market value of decommissioned assets as well as technical skills for the work force of the future.

The spare parts will be available for existing younger assets to further decarbonise the industry, as the carbon typically embodied in remanufactured parts can be less than 20% of a new equivalent. This will also help mitigate supply chain risks such as obsolescence.

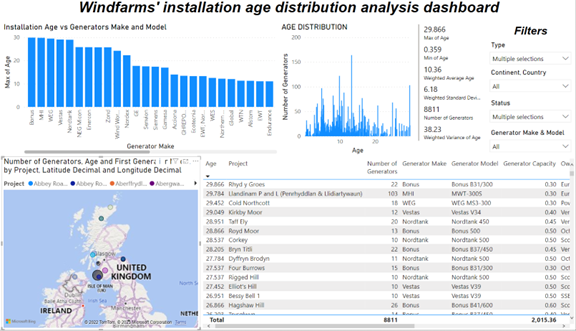

(Picture of interactive analytic dashboard to explore wind farm installations, and wind turbine make and model population age distribution, location, owners, power etc… It comprises bar plots, geographical maps, table, summary figure display and filters, to interactive slicing and visualising the data).

Key Results

RPL has now both data and analytical expertise to evaluate the wind farm installations age across Scotland, the UK, and the world so that it can strategically tackle the projects that are to be decommissioned before they even get to the market. Furthermore, the number, availability and potential market volume can be analysed, in order to focus on the best possible opportunity, according to various criteria that will be set during the duration of the project, once more data on assets is available.

The project, informative leaflet has attracted further interests from other players, and both University of Strathclyde and Renewable Parts Ltd. are collaborating in the Circular Economy Wind Partnership (CEWP), as part of the tripartite Memorandum of Understanding, between SSE Renewables (SSER), RPL and University of Strathclyde. This has highlighted that decommissioning preparation work should start as soon as five years before the actual decommissioning process, so that all paperwork and parties involved are ready.

Strengthening the partnership, SSER and RPL are collaborating to develop a proof of concept of the nacelle and parts processing protocols, and the identified components will be used to develop testing, inspection and remanufacturing techniques, that can be transferable across different turbine makes and models.

(Picture of the leaflet with wind turbine farm in the background).

Benefits for the Company

The KTP will enable diversification of RPL's service offering and support a legacy of competency within RPL, allowing for future process iterations, and expansion of RPL's portfolio post KTP, driving future business growth. RPL already supplies remanufactured products to the major utility and wind farm owners/operators for assets which are half-way through their life. Developing both the business model and the technical capability of evaluating acquisition of wind turbine minor components to be remanufactured and sold to existing and new customers, will unlock a large market for parts that are otherwise hard to find and with long lead time spare. It will promote the creation of local and national feedstock of parts, further securing availability and a sustainable and robust Scottish and UK supply chain.

(Picture or quarter section of component taken from a wind turbine, showing the gearbox housing, inner spur gears, bearings, and other minor components, sitting vertical on a support stand).

Benefits for the Academic Team

Remanufacturing is a topic which has been firmly embedded in several sectors including aerospace, office equipment and automotive but is still at its relative infancy with respect to the renewable energy. This KTP offers an exciting opportunity to establish a leading research activity around the end-of-life extension of complex components.

Life Cycle Analysis (LCA) has rarely been applied as part of a justification process to remanufacture a component. High academic interest is around demonstrating that LCA can be robustly applied to both the part and process and complemented with other drivers such as economic and technology viability.

The validation of the remanufacturing processes will be achieved through the development of novel material characterisation protocols aimed at providing greater knowledge and confidence in the remanufacturing process.

As the project provides the foundation for establishing a world-leading materials processing capability in Scotland and the UK, it will generate an impactful REF case study for the University of Strathclyde. It will also inform undergraduate projects that will develop students' knowledge in turbine decommissioning, remanufacturing and materials characterisation, and Vertically Integrated Projects for Sustainable Development, offering students an exploratory, research-based and transformative learning experience aligned with the University's ethos of "useful learning".

(Picture showing a mound of roller pins to be reused for reassembly of remanufactured component part).

Benefits for the KTP Associate

- A budget to be used for consumables for the project, travel when required, and training, for both hard and soft skills development courses, conferences, and trade shows.

- Access to University of Strathclyde people and resources such as software, hardware, library, as well as membership to associations and/or institutions, accessing their databases and discounted fares on organised professional events.

- Access to University of Strathclyde benefits such as employment status, pension, holidays etc…

- Academic as well as industrial supervision, experiencing first-hand the academic knowledge side as well as the industrial practical side of the project.

- Leadership experience in working with other people.

- Access to a wider academic and industrial team for support to broaden skills and knowledge.

- Widening of professional network with newly forged relations and strengthening the already existing ones.

- The wider support network of the KTP centre and other fellow KTP associates, as well as past associate.

- Increasing his/her employability for the future, wherever that might be, due to all the above experience.

(Picture of remanufactured gear box set, ready for shipping).